Recently, China National Assets Supervision and Administration Commission (SASAC) made an official report that China National Offshore Oil Corporation (CNOOC) successfully applied “the integrated technology of continuous online production and injection of dispersed particle gel for profile control and displacement” for the first ever in the WZ12-2-B17well of Western South China Sea Oilfields. The operation achieved an increase of daily oil by about 30 m3and reduction of daily water production by 150 m3, in the target well group. Provided that the current average annual operation expenses of 40 wells in CNOOC, the annual comprehensive cost reduction can exceed 100 million RMB, compared to that of the conventional profile control and displacement operation. Note that this technology was a patent transformation project of Professor Dai Caili and Professor Zhao Guang’s team at the School of Petroleum Engineering of China University of Petroleum (East China).

“The integrated technology of continuous online production and injection of dispersed particle gel for profile control and displacement” revolutionizes the traditional profile control and displacement operation mode in offshore oilfields. It has realized the innovation from the conventional wellhead operation mode to a novel integrated production and injection operation mode, which consists of platform production, online inspection, online injection and real-time adjustment sections. Compared with the conventional mode, the operating period of this new technique can be reduced by about 40% and the comprehensive cost can be reduced by more than 50%.The successful application of this technology has exploited a new path for the large-scale application of profile control and displacement technology. Moreover, it has provided valuable experience for the transformation of China’s offshore oilfields from secondary oil recovery to tertiary oil recovery. It is of great significance to enhance the effectiveness of water control and oil recovery stabilization in offshore oilfields, and reduce the cost of oilfield development.

Since 2009, Professor Dai Caili’s team has carried out a series of scientific researches with the supports of “The National Science Fund for Distinguished Young Scholars, Key Projects of National Natural Science Foundation,Subject of National Key Basic Research Development Plan (973 Plan), National Science and Technology Major Project”and the R&D projects funded by the national oil companies.Based on the long-term research, a simple, efficient and environment-friendly method of water-based dispersion, controlled ground cross-linking and mechanical shear granulation for the preparation of dispersed particle gel has been proposed for the first time. Professor Dai Caili’s team invented the integrated process and skid-mounted equipment for continuous online production and injection of dispersed particle gel, and have made a series of original innovations in thebulk gel synthesis and preparation of theory and method, , process and equipment, and “DPG Plus” system. Till now, 62 invention patents have been granted (16 in Europe and America), forming a patent group centered on bulk gels for different reservoir environments, integrated method of continuous online production and injection of dispersed particle gel and skid-mounted production device for dispersed particle gel and its preparation method and application.

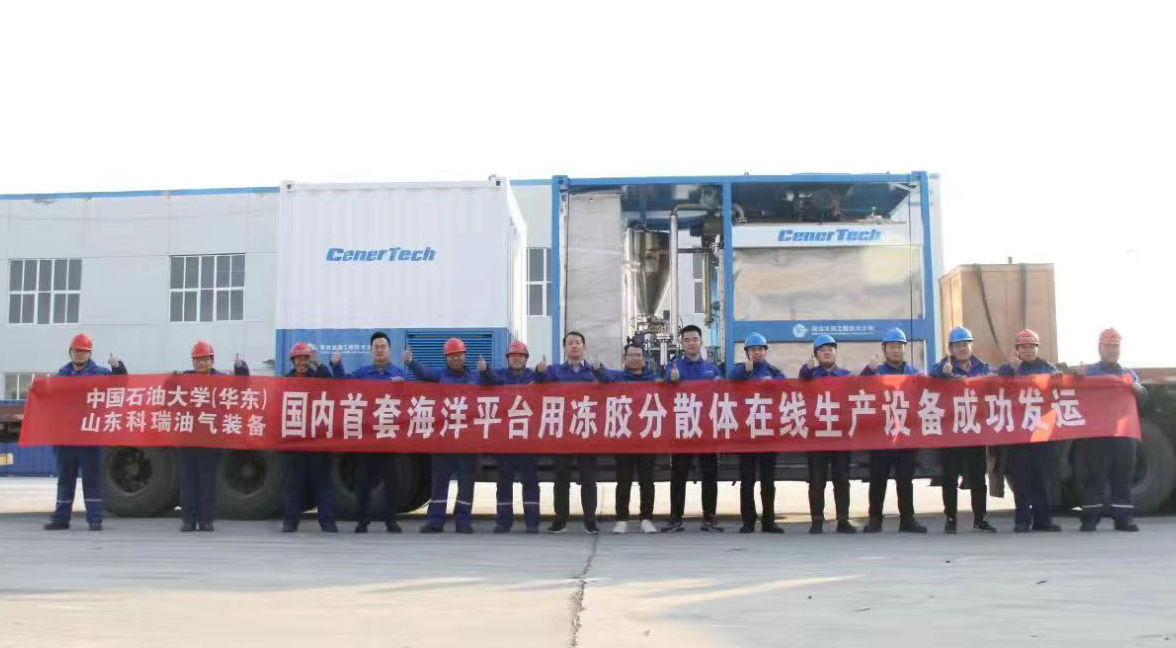

The core patented technology of Professor Dai Caili’s team has been licensed to 21 private oilfield technology service companies with license fees of 15.8 million RMB, and 28 dispersed particle gel industrial production lines have been built, including 11 sets of skid-mounted production equipment. Professor Dai Caili’s team has jointly built an integrated skid-mounted high-end equipment manufacturing base for intelligent production and injection of dispersed particle gel, together with Shandong KERUI Oil & Gas Equipment Company. This equipment has passed the certification of the China/France Classification Society. The patented technology achievements have been promoted to 57 blocks of 23 major Chinese and international oilfields, including Changqing, Shengli, Tahe, Daqing and Bohai, covering more than 80% main oilfields in China. It has become the highlighted research achievements of the National 973 Programand the key technology recommended by the special report of the SASAC. Professor Dai Caili’s technical achievements won the first prize of the technological invention grant by the Ministry of education, the first prize of the technological invention of the China Petroleum and Chemical Industry Federation, the China Patent Excellence Award, the first prize of Shandong patent award and the gold prize of patent of China Petroleum and Chemical Industry Federation.

From: School of Petroleum Engineering

Updated: 2022-05-15