Recently, a series of progress in the field of catalyst was acquired by catalytic reaction engineering team. These research results have been published in top journals ofAngewandte Chemie International Edition, ACS Catalysis, Applied Catalysis B: Environmental, Science Bulletin, ACS Applied Materials & Interfaces,Green Energy & Environment. China University of Petroleum (East China) is the first signing unit. The series of work closely revolves around the core issue of how to accurately design highly efficient catalyst. The structure-activity relationship between catalyst structure and catalytic performance is explored, which provides theoretical basis and experimental reference for the application of supported catalysts in energy and chemical industry.

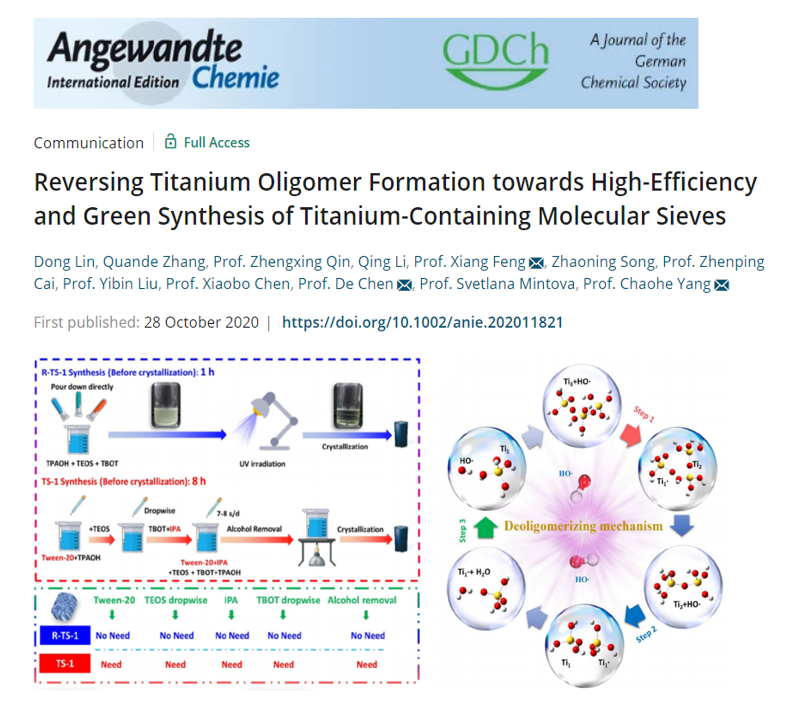

The paper entitled “Reversing Titanium Oligomers Formation towards High-Efficiency and Green Synthesis of Titanium-containing Molecular Sieves” was published onA ngewandte Chemie International Edition. Dr. Dong Lin from School of Chemical Engineering is the first author of the paper, Prof. Chaohe Yang, Prof. De Chen and Prof. Xiang Feng are the corresponding authors.

Fig 1. Reversing Titanium Oligomers Formation

Green and efficient synthesis of titanium-containing molecular sieves is limited by the quantity of environmentally unfriendly additives and complicated synthesis procedures required. This approach successfully reverses the formation of Ti oligomers to match hydrolysis rates of Ti and Si species with the assistance of hydroxyl free radicals generated in situ from ultraviolet irradiation. Moreover, fantastic catalytic performance for propene epoxidation with H2 and O2 was observed. Compared with the conventional hydrothermal method, this approach opens up new opportunities for high-efficiency, environmentally benign, and facile production of pure titanium-containing molecular sieves.

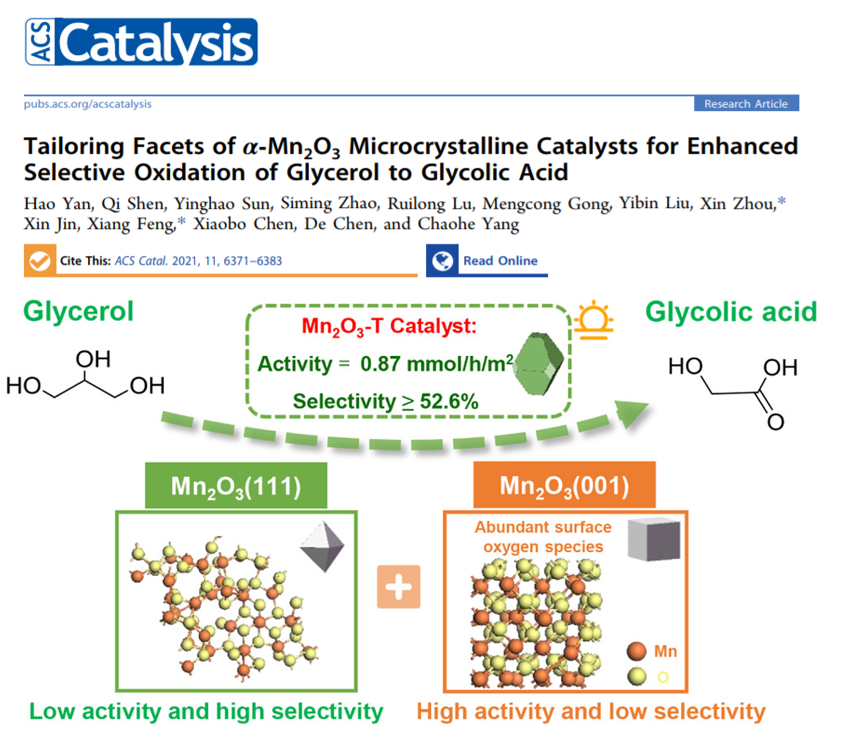

The paper entitled “Tailoring Facets of α‑Mn2O3Microcrystalline Catalysts for Enhanced Selective Oxidation of Glycerol to Glycolic Acid” was published on ACS Catalysis. Dr. Hao Yan from School of Chemical Engineering is the first author of the paper, Prof. Xiang Feng and Dr. Xin Zhou are the corresponding authors.

Fig 2. Accurately control the crystal surface of the catalyst to achieve high-efficiency and selective conversion of glycerol.

Understanding and tuning the crystal-facet-dependent catalytic properties of catalysts are of great importance for the selective oxidation of polyols. Herein, a series of α-Mn2O3catalysts with various morphologies (octahedron, truncated octahedron, and cube) are successfully synthesized for the enhanced selective oxidation of glycerol to glycolic acid. This work could give some suggestions for the design of highly efficient inexpensive catalysts in the glycerol oxidation system.

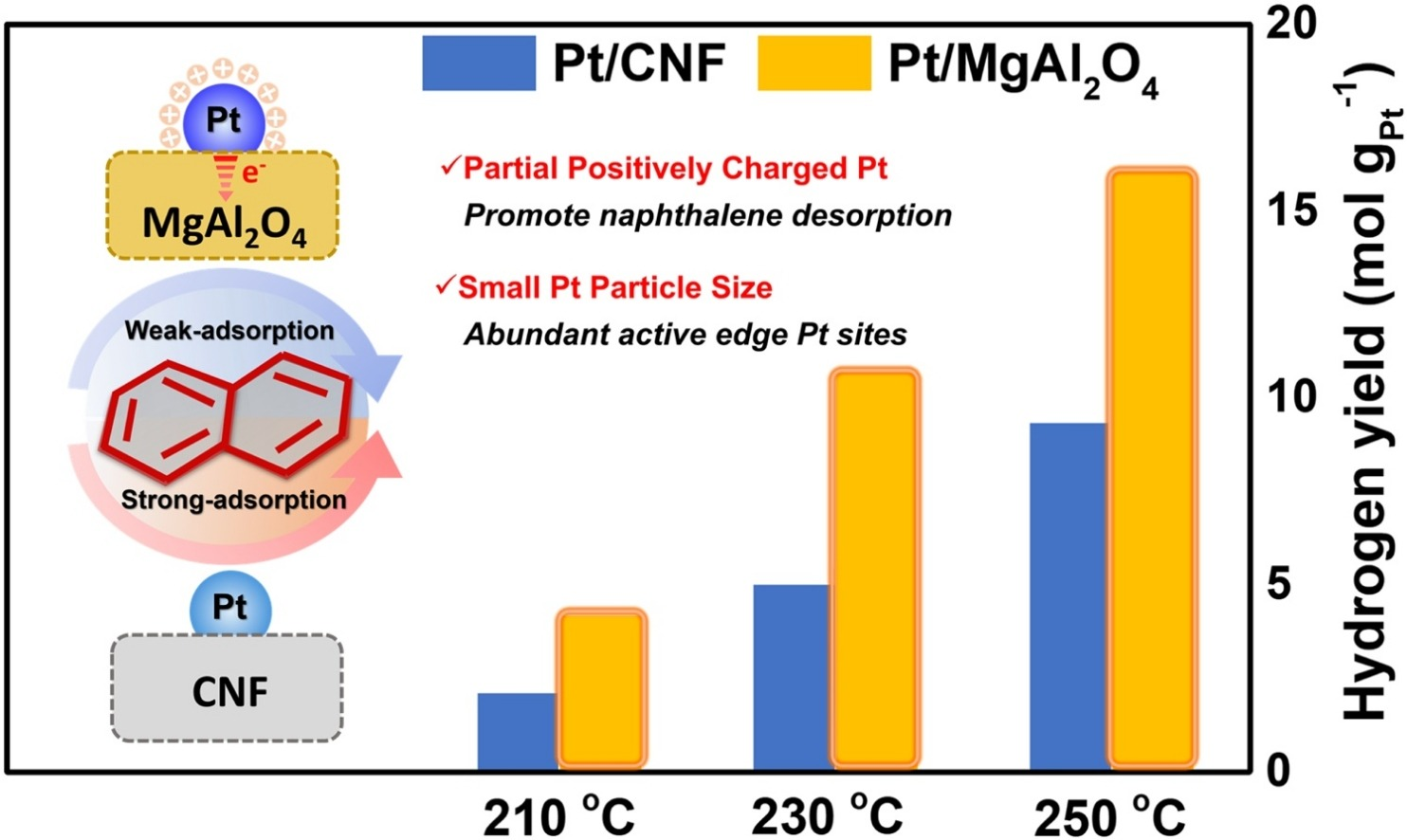

The paper entitled “Partial positively charged Pt in Pt/MgAl2O4for enhanced dehydrogenation activity” was published on Applied Catalysis B: Environmental. Dr. Yongxiao Tuo from School of Chemical Engineering is the first author of the paper, Prof. De Chen and Prof. Jun Zhang are the corresponding authors.

Fig 3. Pt/MgAl2O4 shows robust dehydrogenation activity being twice that of Pt/CNF.

Platinum group metals hold pronounced potential for the dehydrogenation process of liquid organic hydrogen carriers (LOHCs) such as decalin, but the strong adsorption of dehydrogenation product has suppressed the moving forward of these catalysts. The combination of small-sized Pt nanoparticles and facile desorption of products endows tremendous dehydrogenation activity of Pt/MgAl2O4. This study may shed new light on the rational construction of highly efficient metal catalysts for the application of LOHCs.

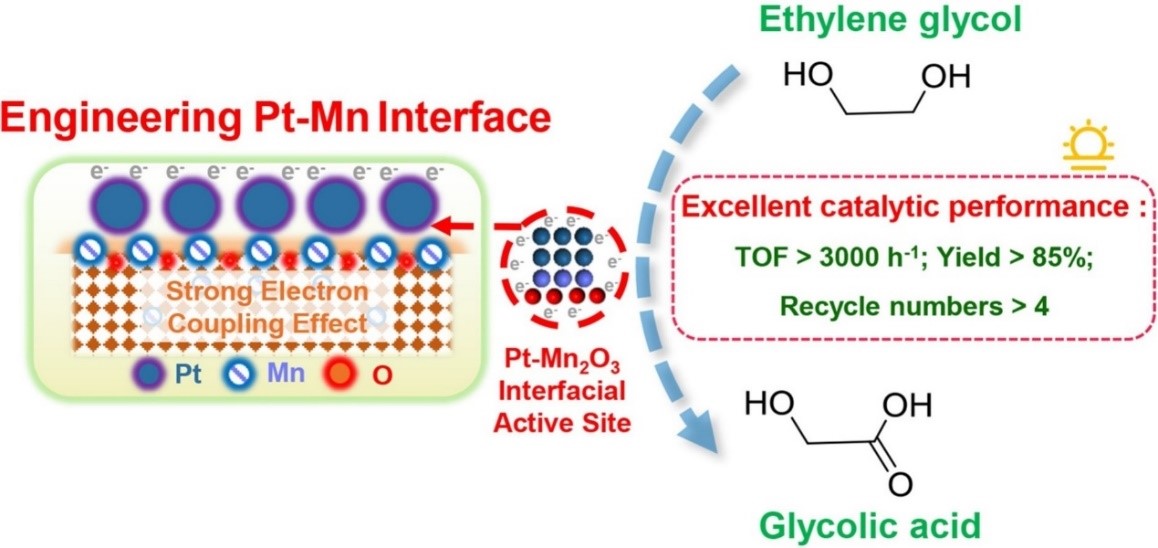

The paper entitled “Engineering Pt-Mn2O3interface to boost selective oxidation of ethylene glycol to glycolic acid” was published on Applied Catalysis B: Environmental. Dr. Hao Yan from School of Chemical Engineering is the first author of the paper, Prof. Xiang Feng and Associate Prof. Yibin Liu are the corresponding authors.

Fig 4. Enhanced catalytic performance of ethylene glycol oxidation was achieved.

This work successfully realized the directional construction of Pt-Mn2O3interfacial sites (by the combination of in-situ doping and impregnation methods) to boost selective oxidation of ethylene glycol under mild conditions. It is found that the pre-distribution of Mn2O3inside support unexpectedly induced the formation of Pt-Mn2O3interfacial active sites with strong electron coupling effect, leading to an unprecedented glycolic acid oxidation activity (turnover frequency: 3196.9 h−1) and glycolic acid yield (86.4 %).

The paper entitled “Rationally constructed Ti sites of TS-1 for epoxidation reactions” was published on Science Bulletin. Prof. Xiang Feng is the first author of the paper and Prof. De Chen is the corresponding authors.

Fig 5. The strategies to rationally construct high-performance Ti sites.

Epoxidation reactions by H2O2(ex-situ or in-situ generated by H2and O2) over titanium silicalite catalysts (milestone in zeolite catalysis) have attracted widespread attention from industries due to simplified operation procedures and reaction processes, mild reaction conditions and reduced environmental pollution. TS-1 is the most widely used titanium silicalites due to its unique framework Ti active sites, hydrophobicity and shape selectivity.

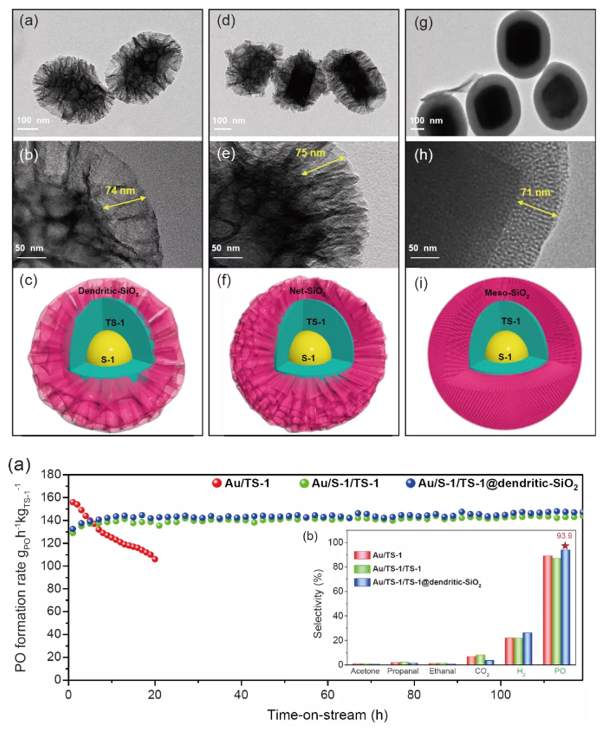

The paper entitled “Engineering three-layer core-shell S-1/TS-1@dendritic-SiO2supported Au catalysts towards improved performance for propene epoxidation with H2and O2” was published on Green Energy & Environment. Dr. Zhaoning Song is the first author of the paper and Prof. Chaohe Yang and Prof. Xiang Feng are the corresponding authors.

Fig 6. S-1/TS-1@dendritic-SiO2 showed fantastic catalytic performance.

TheS-1/TS-1@dendritic-SiO2material with three-layer core–shell structure was developed and used as the support for Au catalysts, whichshowed simultaneously fantastic PO formation rate, PO selectivity and stability for propene epoxidation with H2and O2. Three kinds of SiO2shell morphologies (i.e., dendritic, net, mesoporous shell) were designed, and relationship between shell morphology and catalytic performance was elucidated. The results in this paperharbour tremendous guiding significance for the design of highly efficient epoxidation catalysts.

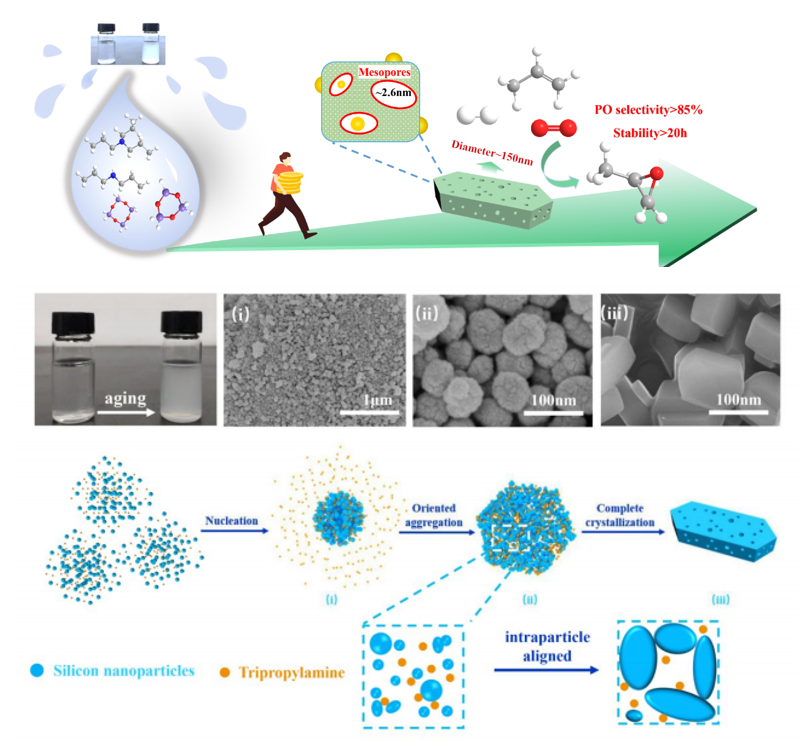

The paper entitled “Mesoporogen-Free Strategy to Construct Hierarchical TS‑1 in a Highly Concentrated System for Gas-Phase Propene Epoxidation with H2and O2” was published on ACS Applied Materials & Interfaces. Dr. Juncong Yuan is the first author of the paper and Prof. Xiang Feng is the corresponding author.

Fig 7. Preparation of hierarchical TS-1 in a highly concentrated system.

Hierarchical TS-1 has attracted enormous attention from both academia and industry due to its remarkable catalytic performance in epoxidation reactions. However, sustainable synthesis of hierarchical-nanosized TS-1 without mesoporogens is still challenging.T his work reports a facile and mesoporogen-free strategy to simultaneously manipulate pore structure and particle size of TS-1 employing the concentrated system.This Au–Ti bifunctional catalyst shows a good PO formation rate with enhanced catalytic stability due to the hierarchical structure. This strategy opens a novel way for the green synthesis of hierarchical-nanosized TS-1 and facilitates industrial development of the Au/TS-1 catalyst for propene epoxidation.

The scientific research team of catalytic reaction engineering led by Professor Chaohe Yang and Professor Honghong Shan adheres to the team spirit of “sticking to the right and doing extraordinary things with one heart”. The research group is characterized by petrochemical industry, aiming at the frontier of the discipline and focusing on the urgent needs of the country. “Two stage riser catalytic cracking new technology for improving light oil yield”, “two stage riser catalytic cracking new technology for increasing propylene production”, “new alkane dehydrogenation technology” and “new technology for direct catalytic cracking of crude oil to produce chemicals” have been successfully developed and applied in industry. The research group has won second prizes of the National Science and Technology Progress Award and provincial and ministerial science and technology awards. The research group has published more than 300 papers in AIChE J., Angew, ACS Catal. and other journals. More than 60 international and domestic invention patents have been authorized. The main research directions of the group are catalytic reaction kinetics, nano-catalytic material design, theoretical calculation, process intensification and heavy oil processing.

From:State Key Laboratory of Heavy Oil Processing

Updated: 2021-06-16