Recently, Jiang Shengjuan, the doctoral student from College of Chemical Engineering made new findings on the research of new energy chemistry and technology which has been reported by Applied Energy, Chemical Communications and Fuel Processing Technology.

The paper Formation of aromatic ring structures during the thermal treatment of mallee wood cylinders at low temperature was released on Applied Energy. Aromatics are important components in the tars from biomass gasification or in bio-oil from pyrolysis. This study investigated the formation of polycyclic aromatics during the thermal treatment of mallee wood at low temperature. The formation of tar was negligible below 200°C but became significant above 230°C. At the same time, the abundance of aromatics also became significant above 230°C. In addition, it was found that some aromatics were formed even at temperatures as low as 150°C. These aromatics were trapped in the resultant chars but could be extracted with solvents (i.e. methanol/chloroform). The abundance of trapped aromatics was different between the outer surface and the centre of the char (cylinder shape). FT-IR and UV-fluorescence analysis revealed that the aromatics contained polar functionalities (e.g. carbonyl groups) on the benzene rings. Some unsaturated hydroxyl aldehyde/ketone intermediates were formed in parallel with the aromatics.

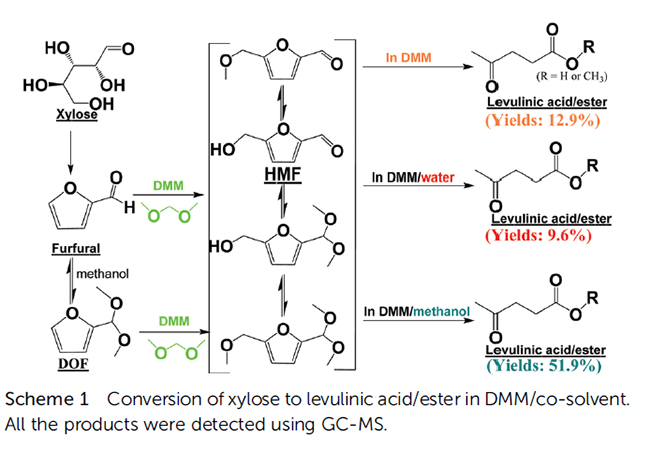

The paper One-pot conversion of biomass-derived xylose and furfural into levulinate esters via acid catalysis was released on Chemical Communications. Direct conversion of biomass-derived xylose and furfural into levulinic acid, a platform molecule, via acid-catalysis has been accomplished for the first time in dimethoxymethane/methanol. Dimethoxymethane acted as an electrophile to transform furfural into 5-hydroxymethylfurfural (HMF). Methanol suppressed both the polymerisation of the sugars/furans and the Aldol condensation of levulinic acid/ester.

The paper Effect of thermal pretreatment and ex-situ grinding on the pyrolysis of mallee wood cylinders was released on Fuel Processing Technology. The study investigated the effects of thermal pretreatment and ex-situ grinding on the production of bio-oil and biochar from the pyrolysis of mallee wood cylinders in a fluidised-bed reactor. The wood cylinders were firstly pretreated at 150–380 °C and were then crushed into small particles before further pyrolysis at 500 °C. Thermal pretreatment alone for wood cylinders could not promote the bio-oil yield. It finds that low temperature treatment with ex-situ grinding greatly promoted bio-oil formation. and high temperature treatment compromised beneficial effects of grinding on bio-oil yield. The balance between thermal pretreatment and grinding needed to be delicately managed to maximise the formation of bio-oil. The pretreatment temperature would significantly affect the composition of bio-oil from the ex-situ grinding pyrolysis. The controlled pretreatment temperature could somewhat “activate” lignin or cause cross-linked bonds in biomass which was responsible for the formation of aromatics.

See more information about the papers:

http://www.sciencedirect.com/science/article/pii/S0306261916313149

http://pubs.rsc.org/-/content/articlehtml/2017/cc/c7cc01078h

http://www.sciencedirect.com/science/article/pii/S0378382016310311